F8500F Series Fiber Laser Inkjet Printer

Product Introduction

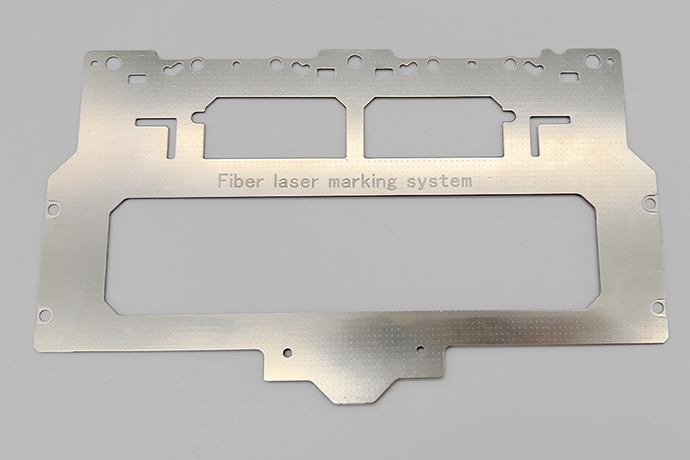

Fastjet F8500F series 20W, 30W, and 50W fiber models feature a compact optical path, flexible installation, and high-speed, high-quality marking under various production environments. The marking content is flexible, not limited by fonts, codes, or graphics, making it an ideal identification solution for industries such as automotive parts, electronics, beverage cans, cosmetics, and building materials.

Product Features

Innovative airflow design for faster and more efficient laser cooling

Highly integrated modular design for easier installation and maintenance

Independently developed touch control system with user-friendly interaction to reduce operational errors

Scientifically precise vector planning logic significantly reduces single marking time

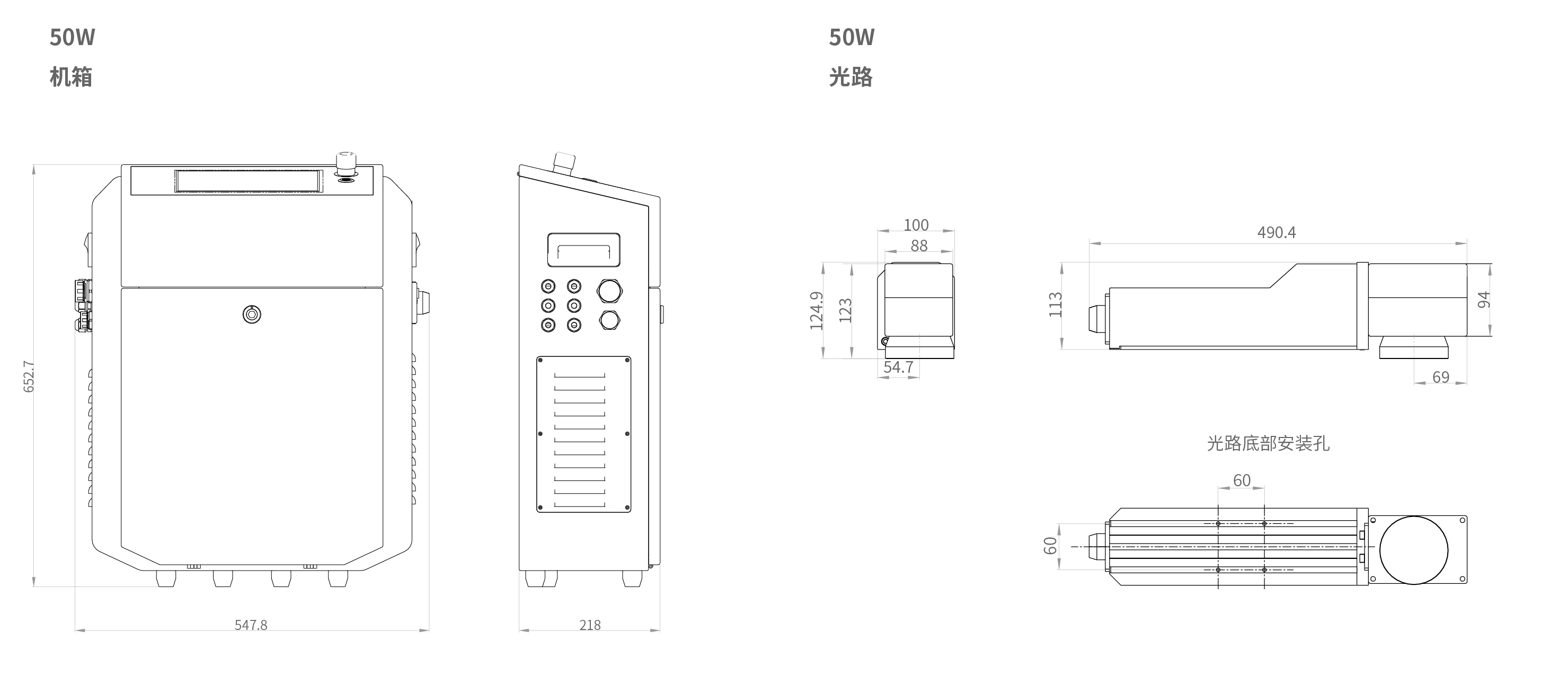

Printing Effects

Product Parameters

Technical Parameters

| F8500F Series Configuration and Parameters | |

| Marking Speed | Up to 2000 characters/second |

| Production Line Speed | Up to 3400 mm/second |

| Optional Lenses | Standard: F160 (110x110) Optional: F73 (50x50), F100 (70x70), F210 (140x140), F254 (175x175), F290 (200x200), F330 (220x220), F420 (300x300) |

| Wavelength | 1055-1070nm |

| Marking Formats | Machine-readable codes (OCR, Data Matrix, etc.) Barcodes: Code128A、Code128B、Code128C、Code39、Code93、QR-Code、 Date Matrix,Aztec-Code,Han Xin-Code Graphics, logos, and symbols Straight, circular, arc, inverted, rotated serial numbers, and batch numbers Automatic date, layered, and time coding with real-time clock Dot-matrix mode provides faster speed for two-dimensional code printing than traditional grid mode |

| Beam Deflection | High-speed digital galvanometer scanner controls |

| User Interface | Personalized touch-screen control with intuitive |

| Laser Tube | Ytterbium (Yb) pulsed fiber laser |

| Communication | UDP、TCP/IP and RS232 |

| Integration | Encoder and product detection trigger input 4 inputs/4 outputs for start/stop signals, machine/operator interlocks, alarm output Excluding safety circuits Flexible beam transmission options (beam extension device/beam steering device) |

| Electrical Requirements | 110-240VAC,~50/60Hz,1PH,0.7kW |

| Cooling System | Air-cooled |

| Operating Environment | Temperature: 5-40°C (41-104°F) Humidity: 10%-90%, non-condensing |

| Approximate Weight | Net weight of entire machine:34kg |

| Note: Maximum marking speed and production line speed depend on application | |

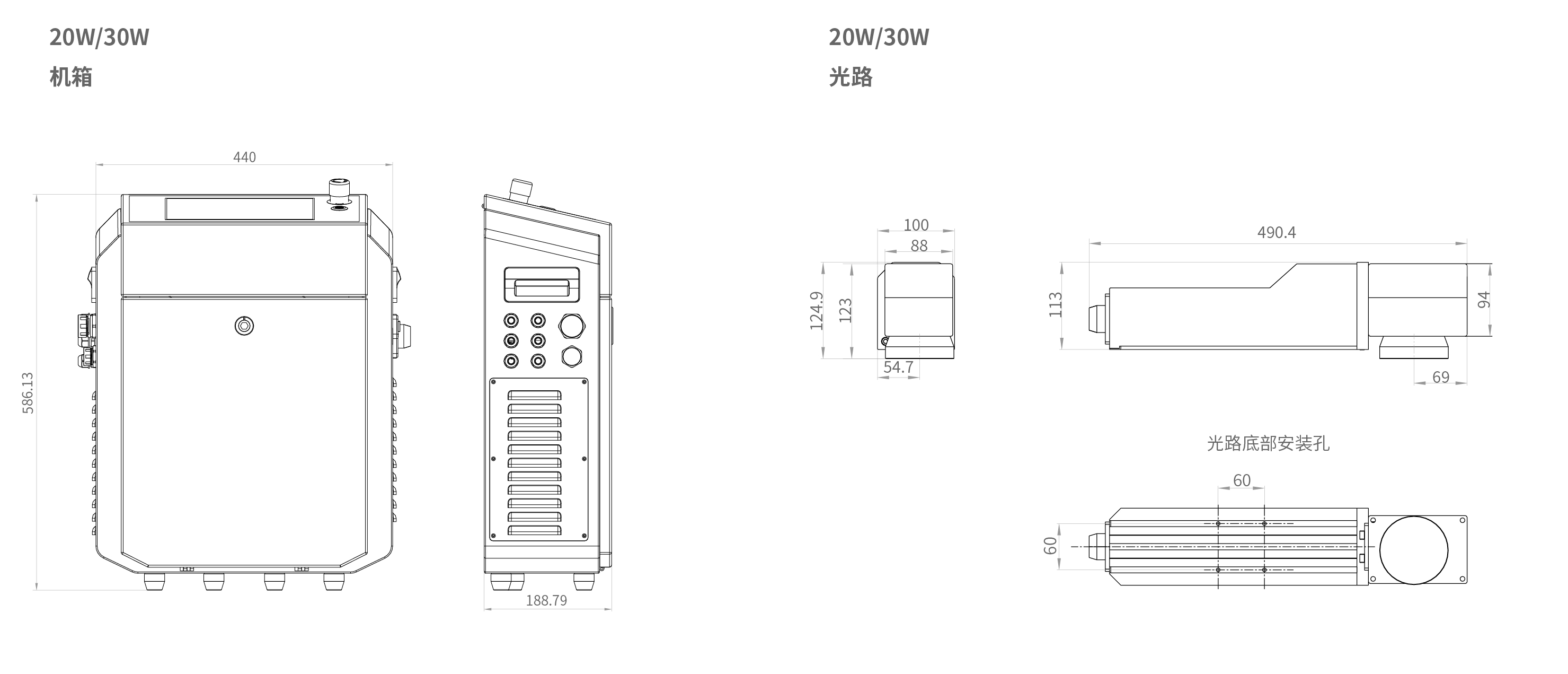

Product Dimensions (Unit: mm)